Container management system

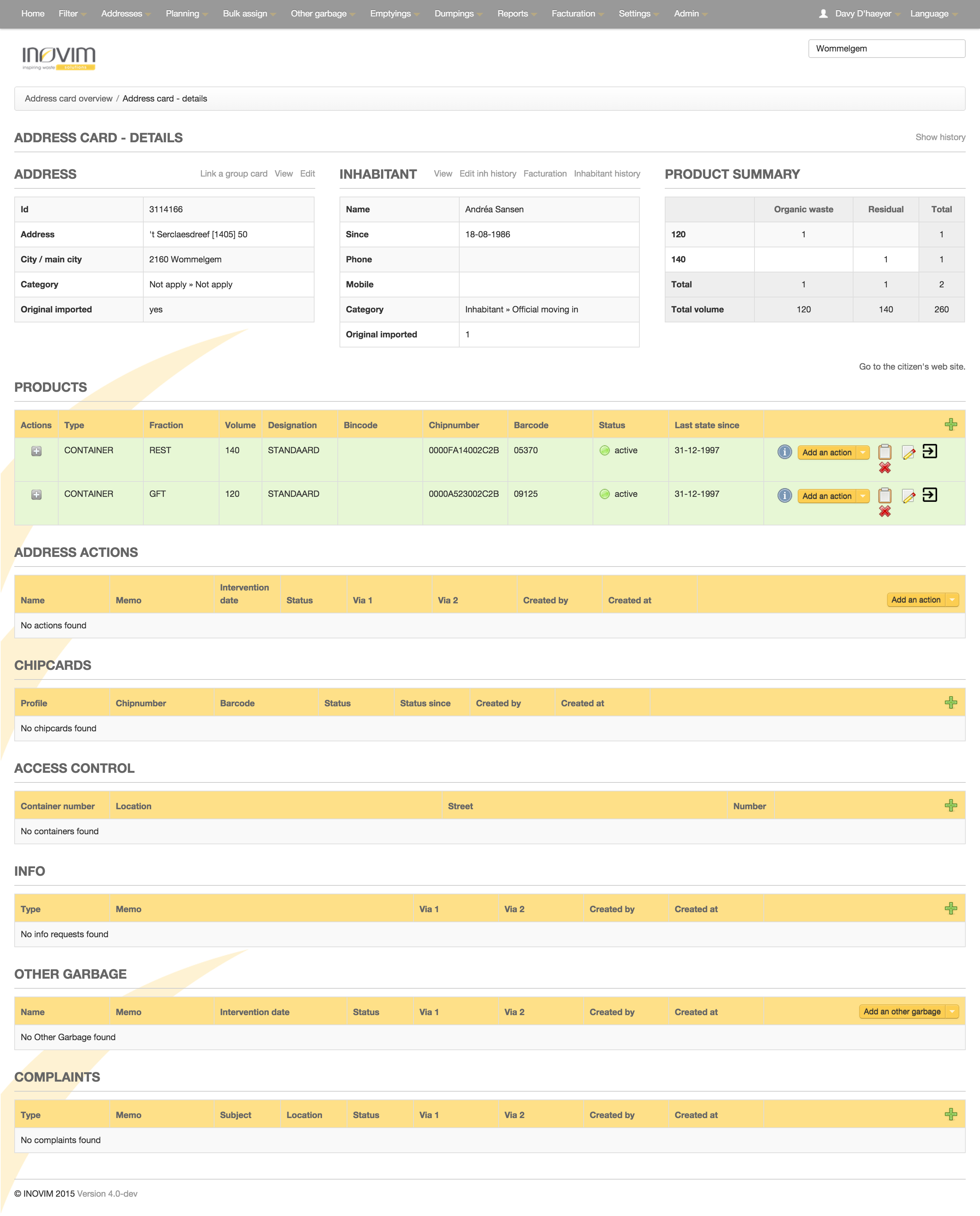

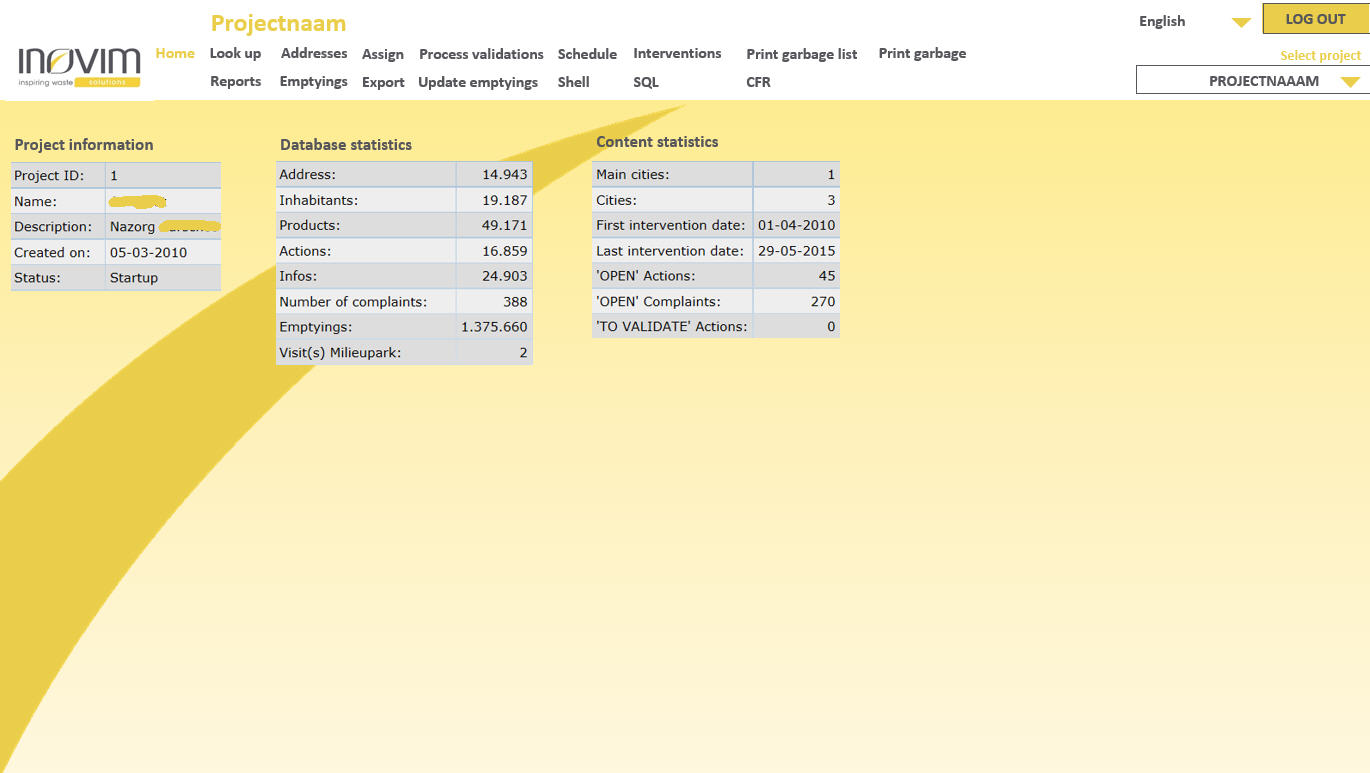

The main product that we work with internally ourselves and that is also used by several of our external customers is our container management system.

We can proudly say that more than 12 million citizens in Belgium and abroad (the Netherlands, France, Portugal, Slovenia, Poland, …) are managed through our container management system.

Based on our experience of many years, we've developed state-of-the-art software that is specifically geared to managing your container depot. CI-Web is a web-based application allowing for a great deal of interaction between municipality, citizens, waste collector and other users. The extent of the interaction depends on the rights assigned to the different players.

The container management system CI-Web includes:

-

Registration of information reports

-

Phone or e-mail contacts with citizens

-

Fax messages from municipalities

-

e-mail messages from the waste collector

-

…

-

-

Registration, follow-up and handling of complaints

-

Generating and processing intervention lists

-

Both on paper and digitally through a PDA or tablet PC

-

-

Follow-up of interventions

-

Deliveries

-

Volume changes

-

Repairs

-

…

-

-

Registration and scheduling of calls for waste collection on demand

-

Bulky household refuse

-

Prunings

-

…

-

-

Drawing up of all kinds of reports

-

The reports can be retrieved and exported 24/7.

-

The assets of our container management system are:

-

Web-based: no installation required + can be set up really quickly

-

User-friendly: the software is easy to adjust to your wishes

-

Dummy-proof: the CMS has been designed such that it is almost impossible to make faults. Ordinary users cannot adjust or remove business-critical information.

-

Direct link with the field: all actions performed in the field are directly visible or all actions that have been created can be made visible by field workers.

-

Comprehensive reporting: comprehensive reporting tools are available 24/7.

-

One overview for all your bins, containers, collective containers, access cards and visits to the waste collection centre.

You can search by:

- address data

- residents' data

- product data

- action data

- collection route

- collective container

- complaints and their status

- information reports

The basic software can be extended with several modules:

-

Collective containers

-

Invoicing

-

Reporting

Click on the module in question to obtain more information about it.

You would like to watch a demonstration? Please don't hesitate to contact us. Here you can see some movies about our software.

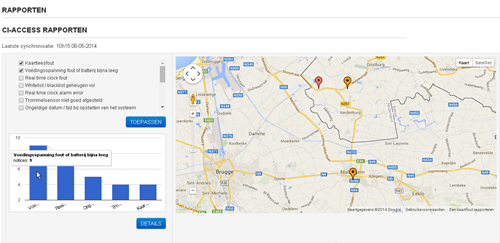

Collective bins

Next to the management of two-wheel bins and/or four-wheel containers, you can – through this module – also fluently manage your collective containers.

Through the dashboard, you will see with a single glance

-

for which containers malfunctions have been reported, distinction being made between malfunctions that do not directly affect the proper functioning of the container or malfunctions that prevent its further use. Obviously, the priority for corrective interventions must be on the container that cannot be used any longer.

-

What is the battery's remaining voltage?

-

At which level the containers are being emptied?

-

Which containers are being used most or least?

-

…

With this module, you can

- create collective containers,

- establish which households have access to these containers,

- set the access hours at which containers can be used,

- establish when containers are closed (e.g. on New Year's Eve),

- see who was the last person that had access to containers,

- see when the previous maintenance was carried out

- ...

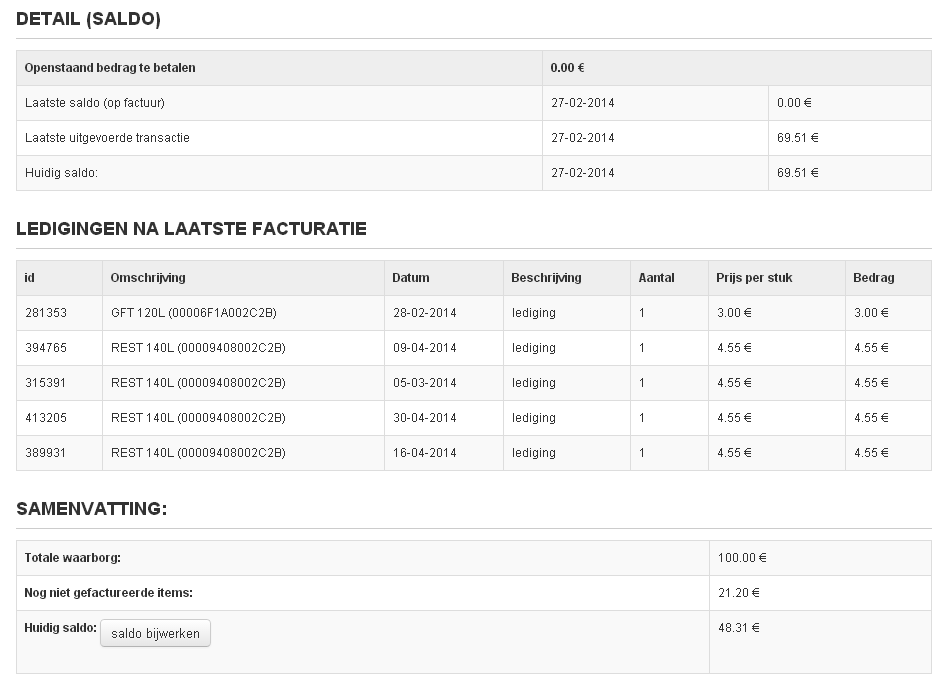

Invoicing

Using the invoicing module, you can as of now

- check at address level what the actual situation of that address is,

- whether they still have sufficient reserve credit to offer waste or to go to the waste collection centre (in case of pre-invoicing) or how many times a certain address already offered waste (in case of post-invoicing),

- ...

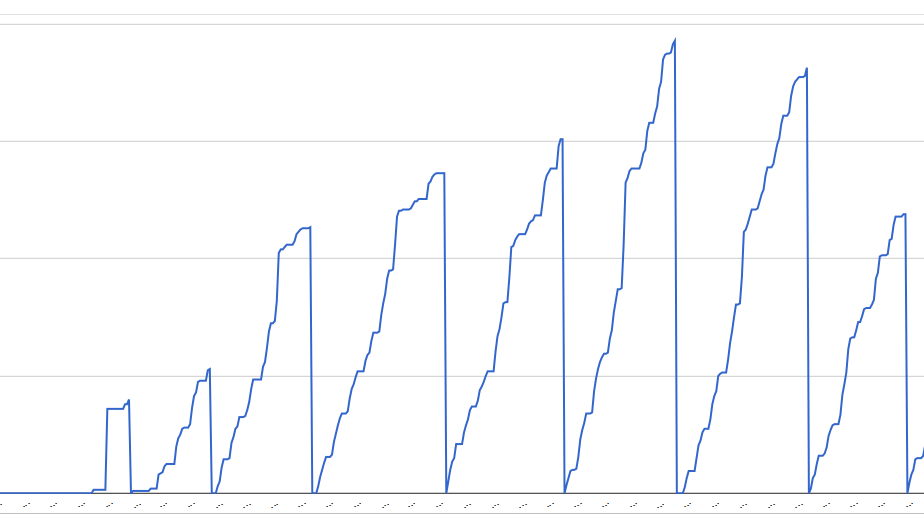

Reports

Next to the possibility to consult data, you can also export many different reports as MS Excel files so that you can use these data in presentations or are able to analyse them in greater detail.

Lots of standard reports and export tools are available, including the option to select a period to which the report should apply. All reports can be retrieved by qualified profiles on a 24/7 basis. You cannot only consult these data but also export them to MS Excel.

We offer reports in the form of a QlikView report. QlikView is a modern Business Intelligence (BI) tool for data analysis, dashboards and reports. This tool enables you to retrieve reports online and in real time. Once you've logged in, a couple of clicks (or "Qliks") suffice to consult standard information but also to arrive at other insights at a glance.

Upon the customer's request, we can, next to the information that has been registered in our container management system, also create a link with other data systems (e.g. your bookkeeping, ERP, hour registration tool...) to enable state-of-the-art reports and dashboards that are geared to the customer's specific needs and wishes. With this powerful, intuitive programme, you will – very rapidly and in a flexible way – gain insight in the key performance indicators (KPIs) defined by you, enabling you to respond adequately. Please don't hesitate to contact us free of commitment if you wish more information about this.

Below, you'll find a couple of examples of standard reports. It goes without saying that the content of these reports will be adjusted to your specific situation.

Chips

INOVIM can support you by supplying all kinds of chips: 134,2 kHz RO, 134,2 kHz HDX, 134,2 kHz FDX, 125 kHz FDX, 125 kHz HDX, …

To standardise the many different types of chips, frequencies, scanning methods and coding, a number of international standards have been developed over the past few years. To make things more clear, we will now provide you with a short description about transponders, etc.

The chip used in the waste logistics system is actually a transponder. The word transponder is a contraction of:

-

transmitter (sender) and

-

responder (receiver).

The word 'transponder' is a collection noun for all information carriers that have an antenna and a memory that can be written upon or read contactless.

Transponders consist of microelectronic components, the transmission and receiving antenna and an energy storage and data storage medium.

The chips used in the waste logistics system are so-called passive transponders. This means that the transponder does not have an energy source of its own (e.g. in the form of a battery). The chip receives its energy from electromagnetic radiation coming from a reading unit.

Construction models

Chips are available in many different construction models. For the waste industry, the most frequently used models are as follows:

-

in the chip nest: the chip is mounted in a special enclosure (the so-called chip nest enclosure) below the projection.

-

through the chip clip: the chip is slid in a special enclosure at the front of the container (is predominantly used in Kliko containers or in containers that have no chip nest à in this event, the slot is milled into the front side of the container.

-

The pin-shaped model is used for containers that do not have a chip nest. At the top of the container's projection a small hole is drilled into which the pin is pushed.

Types

For the waste industry, there are three types of chips:

-

Read-Only (RO) chips are chips that have a unique identification number. This number is programmed into the chip by the manufacturer through a laser. The chip is 'closed', which means that it is impossible to write any information on the chip or to remove information from the chip.

-

One Time Programmable (OTP) chips usually contain a part in which the manufacturer has programmed a unique identification number. This is usually called the 'static' part. As with Read-Only chips, this number cannot be changed or removed.

Next to this static part, the chip also contains a part on which specific information can be encoded such as a waste code, volume code and separately defined chip number with area (or city) code. All this information is written onto the 'semi-static' part of the chip. Normally, this information cannot be changed (= locked), hence the name: One Time Programmable.

-

Read Write (RW) chips have – apart from the unique identification number and the semi-static part – another space onto which the supplier can programme information as he wishes. This read/write chip allows to write information on emptied volumes in the chip itself. This is usually the date of the emptying intervention and the weight of the emptied content. All this information is written onto the dynamic part of the chip.

The city code can be used for a positive verification of the chips. This implies that the identification system is set up such that only chips of one particular city code area can and may be emptied. Containers with a chip with another city code are not emptied. To use this feature, the identification system must be suited for it.

A similar positive verification can be performed on the fraction code. If the identification system is suited for it, the system can be conceived such that, for instance, only VFG-containers can and may be emptied. Containers with a chip with other information are not emptied.

Standards and guidelines

As already written in the beginning, a number of international standards and guidelines have been drawn up.

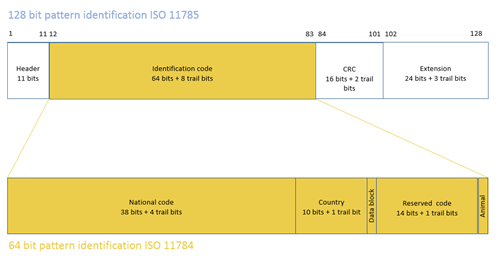

The ISO 11784 and 11785 standards describe the identification by way of radio frequencies (RFID). As described above, it is necessary that the information (data stream) given by the transponder can be interpreted by the receiver. Usually, this data stream is composed of so-called data bits describing the identification code and the number of bits that is being sent.

-

ISO 11784 specifies the structure of this identification code.

-

ISO 11785 describes the way in which the chip is activated (FDX or HDX) and how the information is sent to the receiver.

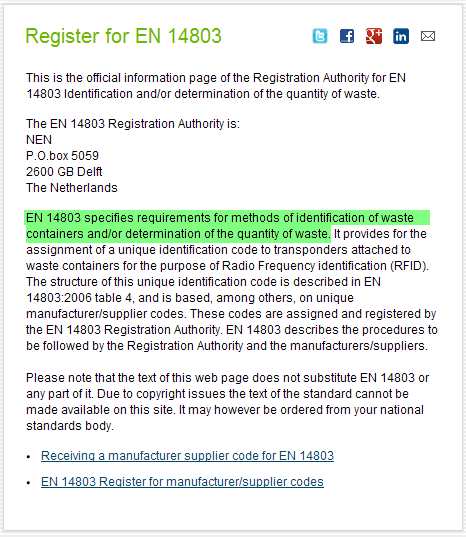

EN 14803 is a standard that has been drawn up specifically for the waste industry; it concerns an addition to the ISO 11784 standard. It describes the general requirements and the verification methods for the identification of waste containers. The EN 14803 standard describes among others which frequency ranges may be used:

-

Low-frequency: chips with frequencies between 125 kHz and 134.2 kHz.

-

High-frequency: chips with frequency 13.56 MHz.

-

Ultra high-frequency: chips with frequency of 868 MHz and more.

STOSAG

In the Netherlands, chips for the waste industry must meet the STOSAG standard (Stichting Open Standaarden Afval and Grondstoffen - Foundation establishing Open Standards for Waste and Raw Materials). Obviously, we deliver chips that meet this standard.

In the above figure, the data structure has been described according to ISO 11784. This description can be regarded as the standard for the waste industry; as such, the chip can be read by all identification systems of the major suppliers. It more in particular concerns a 64-bit identification code. The following table explains how chips are deployed within the waste industry.

|

Bit position |

Description |

|

Bit no. 1 |

This position is set at ‘0’. This indicates that it concerns a chip for the Industrial sector. The "1" stands for the animal sector. |

|

Bit no. 2 |

This bit must be set according to the type of transponder. More in particular: 0 = read only and 1 = Multi page |

|

Bit no. 03 – 32 |

According to the standard, the 10th bit is set at 1. The other bits have value 0. This sequence is reserved for future applications. |

|

Bit no. 33 – 42 |

The manufacturer's of supplier's code. These codes arre assigned and managed by: NEN, EN 14803 Registration authorities and NMI (Nederlands Metrologisch Instituut - Dutch Metrology Institute) |

|

Bit no. 43 – 64 |

Unique serial number (identification number) that is programmed into the chip by the supplier or manufacturer. The latter is also responsible for the unique nature of this number. |

Herewith, the programming method and the structure of the identification code are established for the different types of chips. However, as described before, with OTP and RW chips it is possible to programme information into the chip. The way in which this must be done and its structure have not been defined. Here, suppliers can save information in the way they wish. As for the purchaser, it is possible that a next supplier can read the identification code but not the specifically programmed part. That is why we prefer to use the Read-Only variant to ensure complete independence from whatever supplier.

Cards

Next to chips for waste containers, INOVIM can also support you with the delivery of all kinds of chip cards and badges with which citizens can identify themselves at access control systems for underground or above-ground collective containers, waste collection centres...

The badges can be supplied in a wide range of different chip technologies and or frequencies:

-

MiFare 1K

-

EM 125 kHz

-

Tiris

Other chip variants and construction models are possible as well:

-

Chip card format

-

Keyfob, also referred to as key ring chip

-

Clamshell card: this card has a cut-out through which it can be attached to a key ring or key cord

At request, these badge can be imprinted fully according to your wishes, e.g. in full colour, with your logo or another image, with a bar code and/or a unique number...

Access control system

We deliver an access control system created on the basis of

-

Our experience of many years in the field of access control systems for underground containers

-

The development and production of electronics

-

Market requirements and wishes

The electronic system that we offer has very few loose parts, which makes it very easy to integrate and maintain it. Combined with the unit's austere design, the many functionalities and the simple lock, this access control system is a fine piece of high-quality engineering.

A complete system includes:

-

Access control system in enclosure and cable tree (with "automotive connectors”)

-

It can be equipped with different types of readers, for instance MiFare, EM, 134,2 kHz FDX

-

-

Sensor

-

Battery pack

-

This is a lithium battery (life span of +/- 2 years), no external power supply is provided for

-

-

Servo lock

-

Only badges that are listed as authorised badges (whitelist) can open the drop flap. Other badges are registered but the flap will not be unlocked.

-

Functionalities:

INOVIM supplies a system with the access software being geared to the control electronics as is used on the containers.

The following functionalities can be set using office software, after which the control electronics will also apply these functionalities:

-

4 possible dial-up times : our electronics can handle 4 points in time. This means that also during the day data can be retrieved or sent to the electronics.

-

Daily closing off of systems. A daily closing hour can be set. This way, systems can be closed off between, for instance, 23.00 and 06.00 h am (limiting noise nuisance)

-

Once-only closing off for more than one day, for instance from 31 December 18.00 h until and including 1 January 13.00 h, such to prevent that fireworks are thrown into the systems.

-

Setting of "almost full warning" and indication whether this should be communicated forthwith.

-

The "almost full warning" is based on the number of drops and can be set for each individual container.

-

Setting of "container full warning" and indication whether this should be communicated forthwith.

-

The "container full warning" is based on the number of drops and can be set for each individual container.

-

Option to grant access to all badges.

-

Working with an individual whitelist (list of authorised cards) per container.

-

Setting of time span between offering of badge/unlocking and the actual opening of the flap.

-

Chip cards can also be given a balance.

-

Once the balance has been spent, the flap cannot be opened anymore.

-

Option for temporary use of chip card: it can be stored in the access control memory whether or not the cards have a limited useful life span. This implies that the system grants access to a chip card for a limited period only (for instance from 10 April up to and including 15 April: only in that period the card grants access, not before this period and not afterwards either). Obviously, it is possible to set another period for the same chip card once this particular period has expired.

Special option / replacement of other access control systems: the INOVIM access control system can also replace other existing systems. This way, existing access control systems from Bwaste, Micodata, WSS and Sulo can be easily replaced.

Technical specifications :

| Power input range: | 9V up to 18V, average power consumption: 120 mA |

| Operating temperature range: | -20°C up to +55°C |

| IP-class: | IP 67 |

| Lock interface: | PWM at 5V, period of 0,5 up to 2mS, up to 350 mA |

| solenoid on input voltage, up to 500 mA | |

| Sensor interface: | passive (no reed switch) |

| active (PROX sensor) | |

| Inputs/Outputs: | RS 232 interface, parameters can be set |

| 2 digital inputs, up to 60V | |

| 2 digital outputs, input power out, positive | |

| Display: | LCD-display, 160 x 80 dots, graphics, 10 x 21 characters |

| Activation push button | vandalism-proof push button, stainless steel |

| optional sensor or piezo | |

| GPRS communication | programmable |

| Automatic warnings | container full warning |

| container almost full warning | |

| Operating modes | all chips are allowed |

| only chips that are on the whitelist | |

| allow chips for x days only | |

| allow chips for x times per day | |

| Buzzer | programmable interval during lock activation |

| OTAP | programmable through GPRS |

BIS or Bin identification system

INOVIM offers its Bin Identification System – BIS - for the collection of data of waste bins which were emptied by garbage-trucks. The base for this development were issues like service, easy to use and investment costs.

The complete system is mounted on the lifter. The system consists of a control-unit, antennas and readers. The mounting is simple and easy.

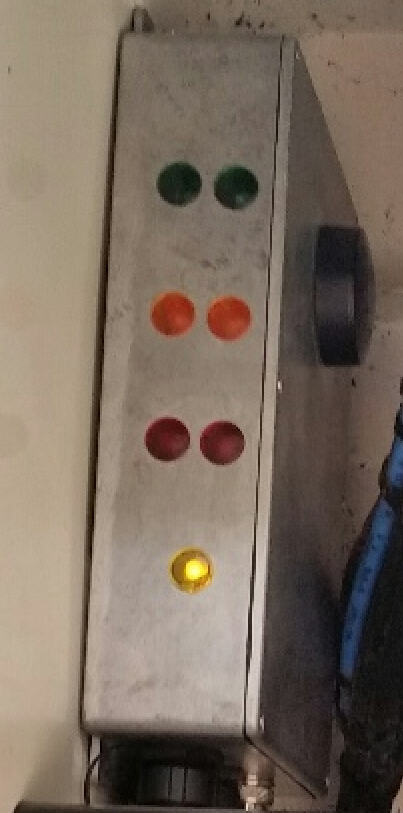

The use of the system is as easy as that: immediately after starting the truck BIS is operational. Driver or loaders do not have to activate the system. The system registers emptied containers and blocks the emptying of containers which are on the blacklist. By using LEDS the status of the emptying is displayed.

The details of the emptying are transferred to a server by GPRS. With the registered GPS-coordinates the tour can be visualized.

BIS identifies all common chip types like 134,2 KHz and 125 KHz FDX, 134,2 KHz HDX.

Our CI-Web software accepts the data of BIS without modifications or interface changes. Of course the data of BIS can be supplied to software of third parties. The communication software makes it possible to communicate with other third party software by using e.g. a STOSAG interface.

BIS has also the possibility to connect to on-board computers. This is realized by using a simple protocol for transferring emptying data to and whitelist or blacklist information from the on-board computer.

Accessories

At simple request, you can turn to INOVIM for purchasing

-

label printers

-

blank labels, pre-printed (in colour or black) or not

-

ink ribbons

-

stickers with waste separation rules

-

fraction stickers

-

PDAs

-

…

Please don't hesitate to contact us if you want more information about this.

MACI & BACi

By now, many municipalities have introduced a DIFTAR system or some other form of "the polluter-pays" system, whereby waste is being offered through a combination of minicontainers and underground waste containers.

However, there are lots of situations in which minicontainers cannot be used but where there is no space either for one or more underground containers.

Also in such situations the municipality should and wants to charge the citizens in question in a similar way. For such cases, we've developed two specific products, i.e.

-

the Mobile Waste Container with identification or MAC-i system

-

the Above-Ground Waste Container with identification or BAC-i system

Also in apartment buildings with only a limited number of residents, our systems can offer a practical solution.

MAC-i

Mobile Waste Containers with identification or MAC-i systems are the solution for buildings for which ordinary minicontainers or underground containers are not practical:

-

can be used in apartment buildings: they take only a very limited amount of space

-

the container is easy to move through an ordinary access door

-

emptied using a standard mounting system

-

access control system: only residents with valid chip card have access

BAC-i

Our above-ground containers (also referred to as BAC-i) offer a practical solution

- in areas where the soil is not suited for underground containers or

- where there are so many underground cables and pipes that only an above-ground solution is possible.

Extra info MACi/BACi

To make sure that no water enters through the roof of the BAC-i unit into the container compartment, the roof construction has been fully welded. The roof of the container is made of 2mm thick steel (thermogalvanised).

The frame is completely thermogalvanised according to EN ISO 1461 and consists of:

-

bottom frame

-

bottom flaps

-

crossbeam

-

roof

The side walls are made of 1.5mm thick steel, completely thermogalvanised (sendzimir galvanised).

The bottom frame and the bottom flaps consist of a welded construction in 3mm thick steel. The crossbeam operating the flaps is a welded construction in 4 mm thick steel.

The drop flap has a content of 30 litre and the drop hole measures 366 x 250 mm. As the drop flap opens to the inside, no water can penetrate into the container compartment. Because of the special lock construction with several locking instances, the waste can but fall through when the flap cannot be opened anymore.

The whole container is excellently protected against adverse weather conditions.

An important additional benefit is that both the flap construction and the identification system of the BAC-i are fully exchangeable with those of the MAC-i. This makes their maintenance much easier.

Colours:

As for the MAC-i, the BAC-i is also available in any RAL colour.

They are painted using a two-part painting process. The two-part paint offers very good adhesion as well as strong resistance against the deforming of metal. After the layer of paint has been applied, an extra anti-graffiti coating is applied (optional). This ensures that graffiti can barely adhere and is easy to remove.

Technical specifications :

MAC-i 800 / 1100

Dimensions MAC-i: 70 x 110 x 180 cm (d x b x h) = 800 liter variant

90 x 110 x 180 cm(d x b x h) = 1.100 liter variant

Weight: 150 kg / 160 kg

Volume: 800 liter / 1.100 liter

Mounting systems: with 3 hooks, 2 hooks, 1 hook, Kinshofer

Flap construction: 30 litre

Drop options: also available with drop holes for glass and paper

Access control system: for more information, click here

BAC-i

Dimensions BAC-i: 170 x 118 x 151 cm (d x b x h)

Weight: 350 kg

Volume: 2.000 liter

Mounting systems: 3-haken, 2-haken, 1-haak, Kinshofer

Flap construction: 30 liter

Drop options: also available with drop holes for glass and paper

Access control system: for more information, click here

The bottom flaps are made such that waste percolate or other liquids are caught in the bottom flaps.

The whole container is excellently protected against adverse weather conditions.

An important additional benefit is that both the flap construction and the identification system of the

BAC-i are fully exchangeable with those of the MAC-i. This makes their maintenance much easier.